|

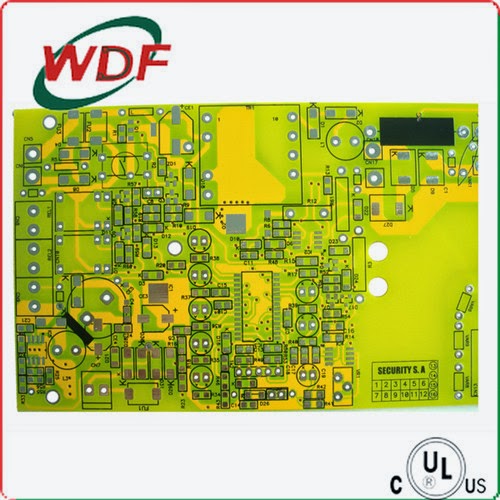

| WDF-PCB-M-31,4 layer,wonderfulpcb.com |

People who order PCB and PCBA from you are in different ways and different needs. So do how you know your client? Do you know what kind of clients they are and can you make a high quote to your clients?

Firstly, you should learn to know your customers. You’d better make a category. There are several kinds of customers. One is the factory which need your boards to make electronic products. This kind of clients are good for you. Because they are indeed asking for your products. Sometimes , if the customers are from rich country, such as Europe countries and USA, then you are lucky, you can quote for a higher price because they are care more about the quality and leadtime. The other one is a distributor who is care more about the money. Everytime they make a inquiry, then they would bargain with you to get a lower price. So these clients are hard to treat well. So we need more tips to fight against them. We may quote a higher price at first and give ourselves some room to reduce the price.

Before we make a quotation to our clients, we ‘d better make a survey on our clients. We can learn more about our clients if they have a factory and what products are they produced, how many pcb they would need in a year and the most important thing is which country are they from. We need to know the situation of the country in this competitive world. In other word, we should deeply know how is our clients.

I think if one can make some analyses before we make a quotation to our clients. We can hold our own advantage and make a good relationship with our clients. There is a proverb saying so: Opportunities will always be people who are prepared.

.jpg)